Shao-jun Jiang , Zhi-lai Zhang and Wen-yan Song

A Real-Time Surveillance System for Vaccine Cold Chain Based on Internet of Things Technology

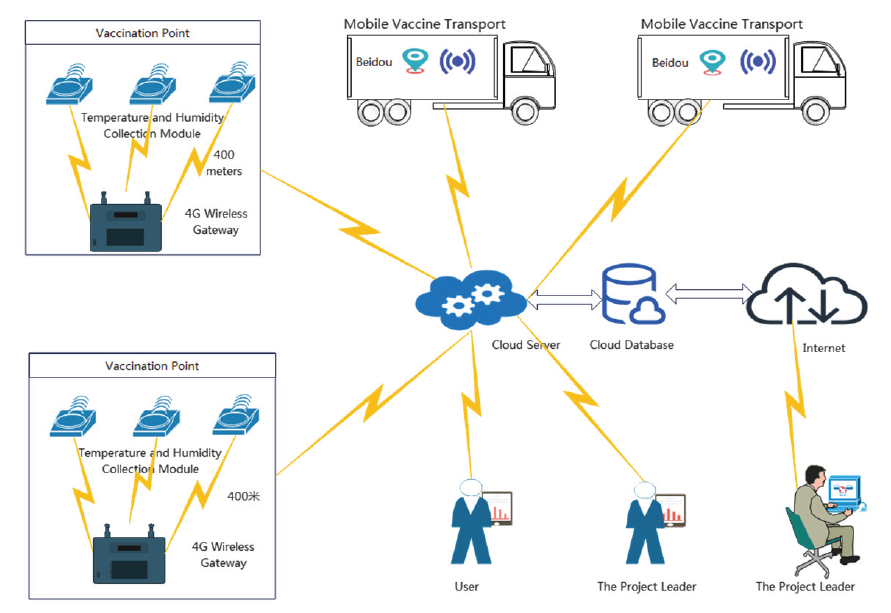

Abstract: In this study, a real-time surveillance system using Internet of Things technology is proposed for vaccine cold chains. This system fully visualizes vaccine transport and storage. It comprises a 4G gateway module, low-power and low-cost wireless temperature and humidity collection module (WTHCM), cloud service software platform, and phone app. The WTHCM is installed in freezers or truck-mounted cold chain cabinets to collect the temperature and humidity information of the vaccine storage environment. It then transmits the collected data to a gateway module in the radiofrequency_physical layer (RF_PHY). The RF_PHY is an interface for calling the bottom 2.4-GHz transceiver, which can realize a more flexible communication mode. The gateway module can simultaneously receive data from multiple acquisition terminals, process the received data depending on the protocol, and transmit the collated data to the cloud server platform via 4G or Wi-Fi. The cloud server platform primarily provides data storage, chart views, short-message warnings, and other functions. The phone app is designed to help users view and print temperature and humidity data concerning the transportation and storage of vaccines anytime and anywhere. Thus, this system provides a new vaccine management model for ensuring the safety and reliability of vaccines to a greater extent.

Keywords: loud Server , Internet of Things , RF_PHY , Vaccine Safety , Wi-Fi , 4G

1. Introduction

In recent years, people have paid increasing attention to life, health, and safety; subsequently, the vaccine consumption in China has sharply increased. In this context, China has paid increasing attention to the supervision of the cold chain transportation and storage quality of vaccines. As high-risk biological drugs, vaccines are susceptible to changes in the surrounding environment, particularly temperature. If the transportation and storage processes of vaccines are not handled correctly, they can easily be damaged , resulting in significant safety risks. Therefore, it is of great significance to monitor the entire vaccine cold chain transportation process through various effective measures to ensure the quality and safety of therapeutic vaccines.

Vaccine cold chain refers to storage and transportation facilities for ensuring the quality of the vaccine. The facilities include refrigerated vehicles, vaccine transport vehicles, freezers, refrigerators, vaccine freezers, vaccine cold packs, ice cutters, and houses for equipment installation, all of which are essential components of an immunization program [1]. The normal operation of a cold chain system is a fundamental guarantee of vaccine quality and immunization programs [2]. The healthy operation of vaccine storage and transportation networks plays vital roles in achieving the goal of universal immunization for children and ensuring the implementation of an immunization plan [3].

Nevertheless, in recent years, all vaccine incidents have been related to the cold chain system, indicating that the traditional cold chain-working mode can no longer guarantee vaccine safety [1]. Ma et al. [4] used the Internet of Things (IoT) to design a vaccine safety system. However, the collecting sensor needed to be wired to the gateway, making this system challenging to implement on-site. Zhang [5] adopted a narrow-band IoT method to design an integrated collector for collecting data and uploading it to a cloud server. Still, the system cost and power consumption were too high to be practical. Despite these shortcomings, the rapid development of IoT technologies, mobile edge computing, and cloud computing, and especially the rapid growth of intelligent sensor networks provide a good foundation for vaccine safety detection systems. It sets a firm foundation for the design of a real-time monitoring system for the vaccine cold chain; for example, providing real-time monitoring and alarm warnings of temperature and humidity conditions in the vaccine transportation and storage environment ensure safe vaccine use [4,5]. This study mainly proposes the overall design framework of the vaccine cold chain system in addition to the software and hardware design of the system. It also analyzes the solutions to problems encountered in the use of the system.

2. Design Scheme of the System

This system primarily comprises a wireless temperature and humidity collection module (WTHCM), 4G wireless gateway module, cloud server monitoring platform, and mobile app. The WTHCM is designed with a low-power and low-cost chip (CH583M) for collecting and encrypting temperature and humidity data and then transmitting it to the gateway module in the radiofrequency_physical layer (RF_PHY) [6,7]. The gateway module is designed using a low-power chip (CH579M); it receives and collects terminal data through the serial port to extend to the 4G, Wi-Fi, and RF_PHY modules, encapsulates the received data based on a protocol, and sends it to the cloud server through a 4G or Wi- Fi module [8,9]. To ensure that the data collected is not lost, the 8M-capacity flash chip is simultaneously expanded through a serial-peripheral interface (SPI) for the collected data to be saved, e.g., in the network or server's abnormal state. Then, the recorded data can be replenished to the cloud server monitoring platform after the abnormal situation no longer exists. The cloud service monitoring platform is developed and designed with ThinkPHP6.0 and AdminLTE framework technology. It uses a friendly operation interface for users' data viewing and downloading, and can also provide a short-message warning function.

When the temperature of the storage environment of the vaccine exceeds a set limit, the administrator receives an alarm message sent by the system and addresses it in time, thereby preventing the long-term invalidation of the vaccine at high temperatures. To make it easier for administrators to view data anytime and anywhere, a mobile app is developed using Qt technology. Administrators can conveniently view the data and connect a Bluetooth printer through the app to create a print backup of the data. This system ensures the safety and security of vaccine storage and improves the efficiency of vaccine management. The functions of the system are illustrated in Fig. 1.

3. Hardware Design of the System

3.1 Hardware Design of the WTHCM

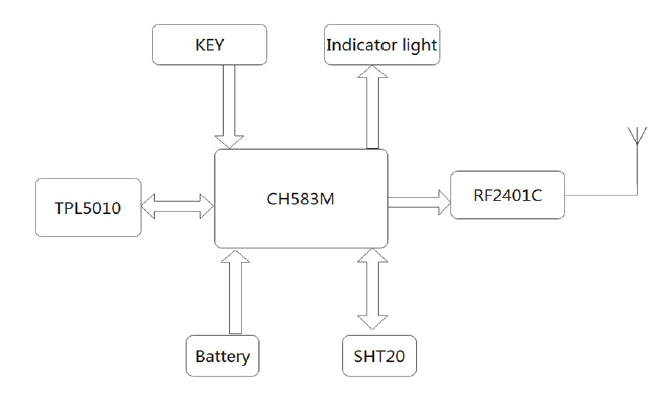

CH583M was used as the main hardware for the WTHCM. CH583M is a synthesizable RISC-V processor core, which meets the requirements for low-cost hardware devices [7]. The CH583M has a working voltage range of 2.0–3.6 V. The system is powered by a 3.0-V lithium battery with a one-time capacity of 800 mAh. It can operate continuously for more than three years at normal temperatures. The WTHCM is also outfitted with two buttons for switching between the working state and stop-working state, and two LED lights to indicate the status. In addition, the WTHCM is outfitted with the SHT20 to collect the temperature and humidity data of the environment. The WTHCM uses an RF2401C chip, i.e., a 2.4-GHz RF_PHY high-efficiency single-chip RF front-end integrated chip, to enhance the transmitting power of the system [10]. The transmission distance of the WTHCM can reach 400 m in an open environment, and it can be utilized in various complex installation environments. In the actual application process, CH583M is prone to crashing when the temperature is lower than -30°C, leading to rapid battery failure and shortening of the label life. To solve this problem, an external watchdog chip—TPL5010—is used to extend the system. Fig. 2 shows a system block diagram of the WTHCM.

3.2 Hardware Design of the 4G Gateway Module

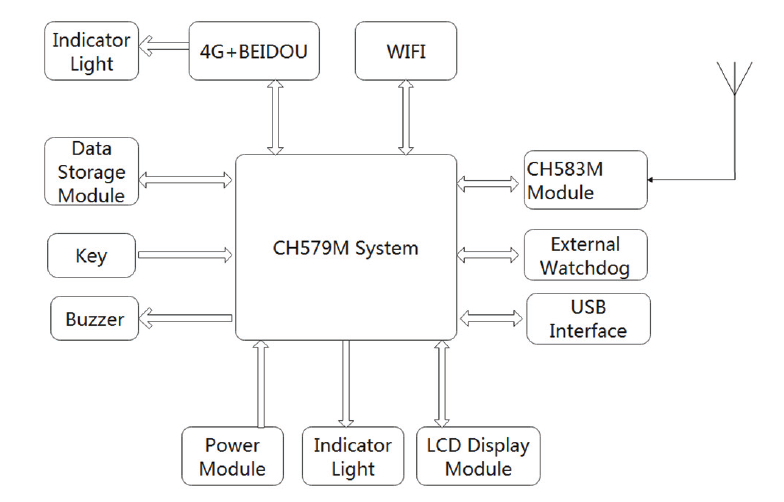

The 4G gateway module uses CH579M as the main processor, and the CH579M chip uses a 32-bit ARM Cortex-M0 as the core. The system's core frequency can reach 40 MHz, and the chip integrates a 257-kbyte non-volatile storage flash ROM and 32 kbyte volatile data storage SRAM. This chip supports the “Bluetooth Low Energy” protocol and is compatible with Bluetooth 4.0 specifications. The chip is integrated with the real-time clock, four asynchronous serial port universal asynchronous receiver– transmitter, and two groups of independent SPIs, with a built-in first-in-first-out memory. The chip also integrates a USB controller and timer. The operating voltage range of the chip is 2.1–3.6 V, which compiles with the requirements of the gateway hardware design. The system block diagram of the 4G gateway is shown in Fig. 3.

The gateway extends the CH583M module through a transistor-transistor logic interface to receive the temperature and humidity values collected by the WTHCM. The gateway is outfitted with a 2.4-inch thin-film transistor (TFT) LCD using an SPI. The LCD displays system information such as the system time, signal quality, server connection, temperature and humidity, and system setting parameters. The module is equipped with a W25Q64 flash chip that is able to store 8M bytes of data, that is, 10,000 pieces of cache data, to prevent data losses owing to disconnection between the system and server. The gateway design alarm indicator and buzzer circuit generate a light and sound signal when the temperature and humidity values received by the gateway exceed the set limits, respectively, prompting the staff to manage these issues in time to ensure the safety and effectiveness of the vaccine.

A key was designed for the module for conveniently switching the LCD interface and viewing the system settings. The power supply part of the gateway adopts the LM2596-ADJ and HT7833 chips; LM2596-ADJ can adjust the output voltage of 3.8 V to supply the maximum 3 A current. Thus, it can meet the working requirements of the 4G module and charge the 3.7-V 2500-mAh lithium battery. The lithium battery can continue to supply power to the system for 48 hours when the power is disconnected. HT7833 provides a 3.3-V voltage to supply power to other circuits. The 4G circuit of the gateway adopts the EC200 series CAT-1 module, which has rich functions and complies with the requirements for 4G communication and positioning. When the system is employed in mobile vehicle transportation, the integrated Beidou module of EC200U is adopted. When used in a fixed position, EC200S can be adopted, thereby reducing the cost and power consumption. Simultaneously, the EC200 series modules extend the network access and server connection indicators to detect the module running status. The system is also outfitted with the ESP8266 Wi-Fi module, which has low cost and good performance. It can comply with the requirement that there is Wi-Fi signal coverage in the place where the gateway is used, and the collected data can be sent to the cloud server through Wi-Fi to reduce 4G traffic consumption and reduce operating costs. The external watchdog circuit is also equipped for the gateway using a TLP5010 chip, which ensures low power consumption, complies with the system requirements, and enables the system to work continuously for 7×24 hours under normal voltage. The gateway extends the USB interface. The interface can be used as a power supply interface, the program download and update interface of the gateway, and a system simulation U-disk interface, making it convenient for setting system parameters.

4. Design of System Software

4.1 Software Design of the WTHCM

The WTHCM programs in the CH583M chip are programmed based on the RF_PHY protocol stack. Each WTHCM has a unique ID consisting of 10 digits, including a six-digit production date and fourdigit daily production number [11]. When writing the program, the decimal number is translated into a hexadecimal number and written onto a secondary IEEE location of the chip. For example, if the 336th label is produced on January 14, 2022, the label number is 2201040336, and the burned data are the four bytes of hexadecimal data 0×83, 0×32, 0×BC, and 0×70.

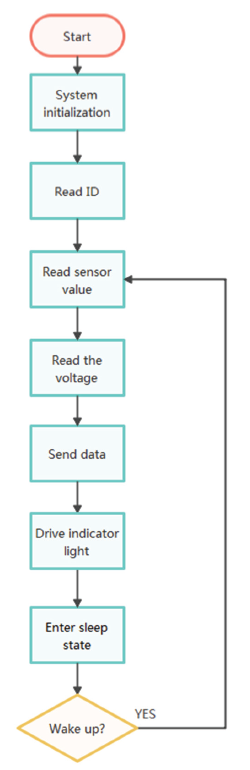

When the WTHCM is powered on and begins to run after the system is initialized, the ID value stored from the secondary IEEE location is read and stored in the defined cache variable [12]. Subsequently, the working status is judged, the SHT20T/H sensor is initialized, and the temperature and humidity values are read and stored in the cache variable. The subfunction adcRead() is then asked to read the chip supply voltage value and store it in the system variable. The corresponding positions are then written in sequence according to the format of the data protocol packet for encapsulating a frame of data, and the packet is prepared to be sent. The format of the protocol packet data is presented in Table 1. The transmitting power is set, the frame of data is transmitted, and the external watchdog is set. The control indicator lights up for 500 ms and then turns off. Finally, the chip sleep timer is set and the system enters sleep and waits for the next awakening. The software design flow of the WTHCM is illustrated in Fig. 4.

Table 1.

| Frame header | ID | Temperature | Humidity | Voltage | CRC16 |

|---|---|---|---|---|---|

| 2 bytes | 4 bytes | 2 bytes | 2 bytes | 1 byte | 2 bytes |

| 0XAA 0XBB | 0X83,0X32,0XBC,0X70 | 0x00,0x50 | 0x02,0x83 | 0x1D | 0XC3,0X35 |

4.2 Software Design of 4G Gateway Module

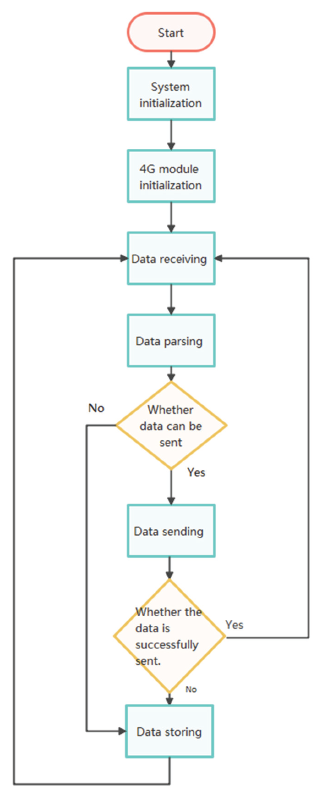

The software design of the 4G gateway module mainly includes a data-processing program and LCD interface program. The data-processing program is mainly used to complete the 4G module configuration, data receiving, data parsing, and data sending programs. The 4G module configuration program primarily contains the initialization and switching status of the 4G module and realizes the functions for module quality reading and data transmission. The data-receiving program is primarily the program design of the CH583M module based on the RF_PHY protocol stack. It is used to receive the transmission data of the WTHCM, and then to send the received data to the core module CH579 through TTL-232 [13,14]. CH579 supplements the data received from CH583M in the serial port interruption program. The data parsing program decrypts the received data, analyzes the protocol, verifies the data, and performs a numerical calculation.

The temperature and humidity values, label voltage, and sensitivity values obtained through the above steps are maintained in the data-sending cache. The data-sending program mainly provides the data transmission between the gateway and cloud server. First, the working status of the 4G module is determined. Assume that the module operates in the data-transmission state. In this case, a handshake protocol is adopted to send one frame of data acquisition to the cloud platform, and then to wait for 20 seconds. If the cloud server returns the frame data, the frame is considered to have been successfully sent; conversely, the frame is deemed to have failed to sent and is recorded in a flash to wait for the subsequent transmission. The format of the gateway data protocol is given in Table 2, and the software design flow of the data-processing program is shown in Fig. 5.

Table 2.

| Verification code | ID | Function | Type | HTCM number | Data time | Date | CRC | End mark |

|---|---|---|---|---|---|---|---|---|

| 1 byte | 4 bytes | 1 byte | 1 byte | 1 byte | 6 bytes | N bytes | 2 bytes | 3 bytes |

The data display program mainly includes a TFT LCD driver and LCD interface program. The TFT LCD screen is expanded using the SPI interface integrated inside the CH579. The driver is developed using the SPI driver function provided by the CH579 system. The LCD system initialization function, screen brush function, picture, number, English letters, and Chinese characters display sub-functions are the main aspects of the design. The LCD interface program mainly includes the main interface program, system parameters interface program, WTHCM configuration interface program, and interface switch for keys, making it convenient for users to operate and view system values and parameters.

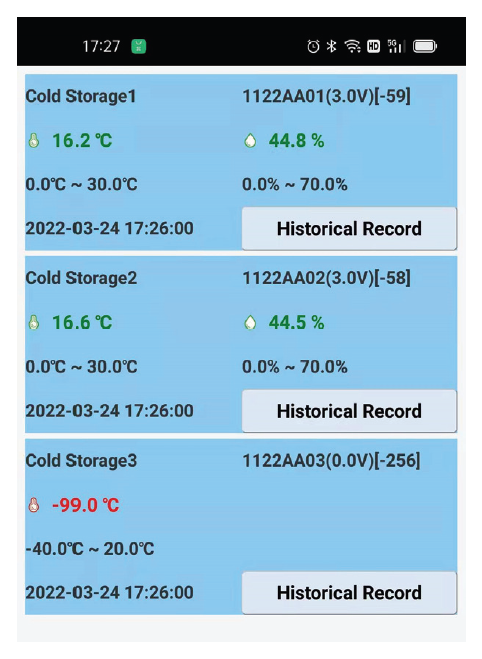

4.3 Software Design of Mobile App

The mobile software program is developed based on Qt C++ for friendly portability and maintainability [15,16]. The software is mainly used to communicate with the cloud server, and may be used to display real-time and historical data of the WTHCM. The main interface for the real-time data display of mobile phone software is shown in Fig. 6. The historical printing program of the mobile phone software is developed in accordance with the Bluetooth Qt module for connecting to a Bluetooth printer, making it convenient for users to download and print historical records for backups.

4.4 Software Design of Cloud Server

The cloud server program occupies a significant position in this system; it is the data center of the entire system and provides the functionality and stable operation of the system. The cloud server program runs on the Tencent Cloud and Ubuntu systems and consists of four parts: a socket server program, database design program, mobile app interaction program, and web front-end program. The socket server program is designed based on the “Workerman” software. It mainly provides data communication and transmission with a 4G gateway and analyzes the received data for processing and storage in the database. The database of the system is developed using MySQL technology. This technology is mainly used to establish the system user information table, equipment information table, probe history record table, alarm record table, and so on. The mobile app interaction program transmits the data of the mobile apps. It primarily adopts the JSON data format to complete the data reading and transmission, and is built on the HTTP protocol. The web front-end program can allow the user to observe a real-time data view, set and view system parameters, view user information, and other functions. It adopts a framework based on adminlet [17]. It includes a system login interface, system display main interface, system department interface, real-time data display interface of measurement points, and measurement point history record interface, which provide operational convenience to the users.

5. System Operation and Test

Before using this system, users first need to visit a website (https://www.120.53.18.190/login/) for registered users. After user registration is completed, the department is inserted. Subsequently, the number of installation points can be determined according to the actual installation environment, and the unique ID of the gateway can be added to the system for registration. Then, the primary attributes of each WTHCM are added for the device to be successfully added to the system. Then, the 4G gateways are configured. The ID of the WTHCM to be used is determined, and the IDs in the corresponding channels of the gateways are filled in. Each gateway can be configured with a maximum of 10 WTHCMs. The alarm threshold is set for the labels, and the port number and IP address are set to connect the gateway to the server. After all parameters are fixed, the gateway is restarted, and the WTHCM is turned on. The gateway receives data from the corresponding WTHCM on the corresponding channel. In this case, a browser or mobile phone app can be used to simultaneously view the measurement point data. The WTHCM can then be placed in the refrigerator in which the vaccine is stored.

When the gateway receives the temperature and humidity values sent by the WTHCM, the alarm limit may be exceeded. The buzzer of gateway began to sound. The alarm indicator blinks, and the characters on the real-time data-display interface turn red. Meanwhile, the cloud server receives the alarm data and notifies the administrator through mobile phone SMS to check the abnormality of the stored vaccine device and manage the issue to ensure vaccine safety.

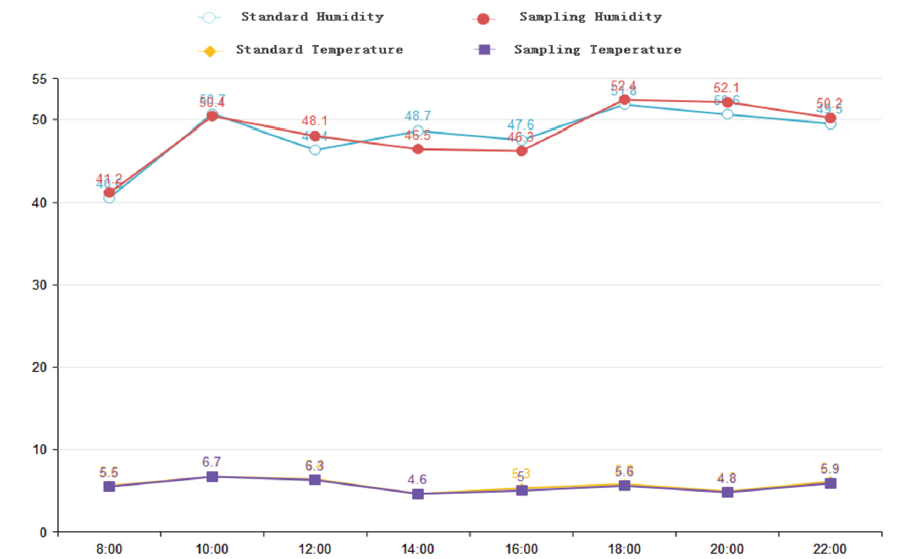

6. System Testing and Result Analysis

In this study, the system was applied to all vaccination sites in the Jinan Centers for Disease Control office, Shandong Province, to realize real-time monitoring of the temperature and humidity in the vaccine storage environment and improve the vaccine safety. A vaccine storage freezer in a vaccination center was taken as the test point, a WTHCM was placed in the appropriate position of the freezer, and an EF- 6D portable temperature and humidity tester is used to conduct the comparative test. A comparison between the system-sampled data and standard test data is shown in Fig. 7. Every day at all eight time points (8:00, 10:00, 12:00, 14:00, 16:00, 18:00, and 22:00), the EF-6D took a standard value. Then, the parameters of the statistical measurement values were compared against the standard to determine the maximum deviation and average relative error. A 4G gateway module was installed in the working area of the inoculation point for data acceptance, processing, and transmission to the cloud platform. The data for 6 days were checked through the cloud platform. The packet loss rate of the data transmission through 4G-Cat-1 and that of the tag data transmission of the 2.4-GHz and gateway data were counted to determine the communication status and stability of the system.

6.1 Error Analysis of Temperature and Humidity Collection Data

Compared with the standard data, the maximum deviations and relative errors of the temperature and humidity data used 24 times within 3 days were counted. The maximum temperature deviation was 0.25°C, and the average phase error was 0.28%. The maximum variation in humidity was 2.3% of the relative humidity, and the average relative error was 1.52%. The collected temperature and humidity data of the vaccine storage environment met the requirements for vaccine storage environment monitoring accuracy.

6.2 Communication Test

The data-monitoring records were checked through the cloud platform, and the gateway was set to report the temperature and humidity data to the wireless temperature and humidity collection terminal every 1 minute. Then, the node packet loss rate was calculated based on the data packets obtained by the platform. After 3 days of testing, it was determined that the terminal sent 1,440 data packets daily. The platform received 4,300 data packets for an average packet loss rate of 0.46%, indicating good communication and system stability.

6.3 System Power Analysis

According to the system test and field use feedback, the system can satisfy the overall requirements for the vaccine storage and transportation environment. The WTHCM sends a frame of data every 15 seconds. Stable data transmission can be achieved by increasing and changing the spending power of the CH583M. It takes 5 ms for the WTHCM to wake up and send a frame of data; the maximum sending current is 100 mA, and the WTHCM sleep current is [TeX:] $$2 \mu \mathrm{A}$$; thus, the latter significantly reduces the power consumption of the WTHCM. Accordingly, it can last for approximately three years. The 4G gateway module adopts a dual-chip design that significantly enhances the efficiency and stability of the system. The system extends the 8M flash chip to ensure the integrity of the system data. The system also extends the 2500-mAh rechargeable lithium battery, which can continue to work for 48 hours even after the power supply is turned off, thereby ensuring the safety and stability of the system data.

7. Summary of the Design

7.1 System Test Conclusion

In this study, a remote vaccine monitoring system is designed based on IoT technology, and an application platform for the IoT is developed based on Tencent Cloud and Workerman to conduct business interactions through end-cloud fusion and realize remote real-time monitoring of a vaccine storage environment. The field test verified that the system was stable in operation and accurate in measurement, and the practicability and reliability of the vaccine monitoring were well-resolved. The system in this study has a low power consumption, convenient deployment, competitive cost, long communication distance, and comprehensive network coverage. It is suitable for vaccine monitoring in various environments and in other drug-monitoring fields with strict temperature and humidity requirements.

7.2 Features and Innovations of the System

The system adopts the RF_PHY wireless transmission mode for data transmission and separates the acquisition sensor from the gateway, which not only facilitates system installation, but also expands the monitoring points of the gateway. To ensure data security, data encryption is implemented to prevent tampering with the data. After several experiments and field feedback, the data packet loss rate can be reduced by changing the transmission power of CH583M, and the data are sent in turns according to the four transmission power levels. Because some vaccine storage environments have significantly low temperatures (under -35°C), the program fleet can easily experience a system crash; the continuous working current is larger, and the battery can be quickly drained. To solve this problem, TPL5010 is added to the baseboard. It is a low-power external watchdog chip. It can ensure the WTHCM can restart after a crash and significantly improve the running time of the WTHCM under low temperatures.

7.3 Future Work

The proposed system operated stably and efficiently under general conditions. However, under extreme conditions, the gateway cannot receive label data if the gateway stops running, and consequently it cannot upload it to the server and the label will have no storage function; thus, data loss events can occur. In the future, to solve this problem, a storage function will be added to the WTHCM, and the communication between the gateway and WTHCM will use the handshake protocol. The WTHCM reduces the transmission frequency and ensures each frame data is effectively transmitted to the gateway; if the gateway cannot receive data and is unable to return the response signal, the data is stored in the memory chips of the WTHCM for the next time the system is normal (such as after data repair. Thus, it effectively guarantees the integrity of the data of the WTHCM.

Biography

Wen-yan Song

https://orcid.org/0000-0001-9889-6017He has been a professor at the School of Economics and Management, Beihang University (Beijing University of Aeronautics and Astronautics), China, since 2022. His main research interests are Failure Mode and Effect Analysis, Quality Manage-ment, and Risk Management. He earned his Ph.D. in Industrial Engineering at Shanghai Jiao Tong University (SJTU) in 2014 and worked as a postdoctoral researcher at Technische Universitaet München (TUM), Germany, in 2016. He has published in the European Journal of Operational Research, IEEE Transactions on Engineering Management, International Journal of Operations & Production Management, IEEE Transactions on Reliability, International Journal of Production Research, and Computer & Industrial Engineering, among others.

References

- 1 S. Reid, "Vaccine safety," The New Zealand Medical Journal (Online), vol. 133, no. 1510, pp. 83-85, 2020.custom:[[[-]]]

- 2 B. Huang, "The new China vaccine administration law: re-establishing confidence in vaccines," Biologicals: Journal of the International Association of Biological Standardization, vol. 61, pp. 95-96, 2019.doi:[[[10.1016/j.biologicals.2019.08.007]]]

- 3 M. Pivetti, G. Melotti, and C. Mancini, "V accines and autism: a preliminary qualitative study on the beliefs of concerned mothers in Italy," International Journal of Qualitative Studies on Health and Well-Being, vol. 15, no. 1, article no. 1754086, 2020. https://doi.org/10.1080/17482631.2020.1754086doi:[[[10.1080/17482631..1754086]]]

- 4 Y . Ma, L. Xu, and Y . Sun, "Utilizing IoT(Internet of Things) technology to build vaccine cold chain monitoring systems," Chinese Rural Health Service Administration, vol. 34, no. 1, pp. 41-43, 2014.custom:[[[https://www.semanticscholar.org/paper/Utilizing-IOT%28Internet-of-Things%29technology-to-cold-Yi/d1b71e1ad88816ce7cb25ac6c1cf16d5306ca19c]]]

- 5 P. Zhang, "Research on vaccine safety collaborative management mechanism from the perspective of cuttingedge technology," Modern Information Technology, vol. 2021, no. 10, pp. 167-170, 2021.custom:[[[-]]]

- 6 J. Stepien, J. Kolodziej, and W. Machowski, "Mobile user tracking system with ZigBee," Microprocessors and Microsystems, vol. 44, pp. 47-55, 2016.doi:[[[10.1016/j.micpro.2016.02.007]]]

- 7 D. A. N. Gookyi and K. Ryoo, "Selecting a synthesizable RISC-V processor core for low-cost hardware devices," Journal of Information Processing Systems, vol. 15, no. 6, pp. 1406-1421, 2019.doi:[[[10.3745/JIPS.03.0129]]]

- 8 X. Shen, W. Shao, Z. Zhang, and P. Xu, "Hotel intelligent guidance system based on ZigBee Technology," Microprocessors and Microsystems, vol. 77, pp. 103160, 2020. https://doi.org/10.1016/j.micpro.2020.103160doi:[[[10.1016/j.micpro..103160]]]

- 9 G. Anastasi, M. Conti, M. Di Francesco, and V . Neri, "Reliability and energy efficiency in multi-hop IEEE 802.15. 4/ZigBee wireless sensor networks," in Proceedings of the IEEE symposium on Computers and Communications, Riccione, Italy, 2010, pp. 336-341.doi:[[[10.1109/ISCC.2010.5546804]]]

- 10 W. T. Sung and T. C. Hsu, "Designing an industrial real-time measurement and monitoring system based on embedded system and ZigBee," Expert Systems with Applications, vol. 38, no. 4, pp. 4522-4529, 2011.doi:[[[10.1016/j.eswa.2010.09.126]]]

- 11 A. S. Deese and J. Daum, "Application of ZigBee-based internet of things technology to demand response in smart grids," IF AC-PapersOnLine, vol. 51, no. 28, pp. 43-48, 2018.doi:[[[10.1016/j.ifacol.2018.11.675]]]

- 12 J. Xiao and J. T. Li, "Design and implementation of intelligent temperature and humidity monitoring system based on ZigBee and WiFi," Procedia Computer Science, vol. 166, pp. 419-422, 2020.doi:[[[10.1016/j.procs.2020.02.072]]]

- 13 J. Mu and L. Han, "Performance analysis of the ZigBee networks in 5G environment and the nearest access routing for improvement," Ad Hoc Networks, vol. 56, pp. 1-12, 2017.doi:[[[10.1016/j.adhoc.2016.10.006]]]

- 14 L. C. Huang, H. C. Chang, C. C. Chen, and C. C. Kuo, "A ZigBee-based monitoring and protection system for building electrical safety," Energy and Buildings, vol. 43, no. 6, pp. 1418-1426, 2011.doi:[[[10.1016/j.enbuild.2011.02.001]]]

- 15 W. Zhou, P. Li, Q. Wang, and N. Nabipour, "Research on data transmission of wireless sensor networks based on symmetric key algorithm," Measurement, vol. 153, article no. 107454, 2020. https://doi.org/10.1016/ j.measurement.2019.107454doi:[[[10.1016/j.measurement..107454]]]

- 16 B. Jia and M. Kang, "Software design of host computer for file transmission in embedded system based on QT," Electronic Design Engineering, vol. 30, no. 3, pp. 122-125, 2022.custom:[[[-]]]

- 17 J. Y u and Q. Bao, "Design of population information system based on ThinkPHP," Information Technology and Informatization, vol. 2022, no. 2, pp. 9-12, 2022.custom:[[[-]]]